Topic 1 : Fabrikam inc sanitation cleaning solutions

Background

Fabrikam Inc. is a manufacturer of sanitation cleaning solutions and equipment including carpet/floor

cleaners, pressure washers, scrubbers and vacuums.

Fabrikam Inc. is a single legal entity based in New York city.

_ Current environment

Products manufactured

• Cleaning equipment

o floor cleaner

o pressure washers

o scrubbers

o vacuums

• Liquid cleaning solutions

o No scent

o Orange scent (subcontracted to a vendor named VendorA)

o Pine scent (subcontracted to a vendor named VendorA)

The production quantity for the finished unscented liquid cleaning solution is 40-liters. IngredientC 'or unscented liquid cleaning solution Is stored in inventory in 50-liter barrels and allocated in 50-liter increments. Two barrels of IngredientC are uses to produce a barrel of unscented liquid cleaning solution.

Production sites

• The Eastern United States facility manufactures equipment.

• The Western United States facility manufactures liquid cleaning solutions.

• Raw materials and finished products are stocked at the warehouse and distributed from the warehouse.

Warehouse facilities

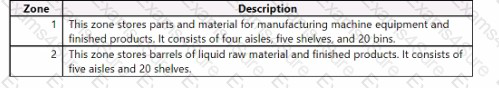

The warehouse consists of the following zones:

_ Requirements

Cleaning equipment manufacturing

You identify the following require merits for manufacturing cleaning equipment:

• Production is Make to Stock and must be scheduled at an operational level.

• Machine equipment is produced on an assembly line. Scheduling must be based on production orders.

• Finished products must be packaged and shipped directly from the warehouse.

• To reduce delivery times and excess inventory, equipment must be produced as needed.

• The ability to schedule production must be based on resource capacity and the availability of required materials.

• Production order operations must be scheduled to start only when capacity and materials are available at the

same time and in the required quantities.

Liquid cleaning solution manufacturing

• Production is Make lo Order and is scheduled at the job level. Products must be manufactured in batches.

• Finished products must be packaged and shipped directly from the warehouse.

• You must be able to calculate the estimated consumption of ingredients and ensure that the amount is divisible by the number of units the raw material «s available.

• Formula changes must be reviewed and approved. You must ensure that approved formulas cannot be deleted or edited. Approved formulas may be deactivated.

• An ingredient used to manufacture unscented cleaning solution is defined as a restricted product. You must be able to automatically print a product safety data sheet (PSDS) with the packing slip for any order that includes unscented cleaning solution.

• Production must be scheduled to start by date and time according to the order that is specified by the production route.

• You must implement a scheduled Kanban rule that meets the following requirements:

o Prevent overloading a work cell for scheduled Kanbans.

o Visualize excess inventory in a supermarket.

o Store products in supermarkets before they are consumed or shipped.

• You must link relevant financial dimension data to the inventory transactions at each site to ensure that you can trace profit and loss figures directly to East site and West site respectively.

• You must set up production operations for sub-contracting of Pine scent and Orange scent solution to VendorA to ensure that a purchase order is automatically created based on estimation of a production order.

Costing

• The price of raw materials used for manufacturing unscented cleaning solution must be tracked based upon commodity exchange pricing. The margin and cost multiplier must be set up for commodity traded raw material.

• You must set up cost calculation groups to ensure that indirect costs that originate in the manufacturing of finished goods are recognized and absorbed into the product cost.

• The production manager needs to set up picking list journals and BOM item consumption.

Reporting

• Production control parameters must be setup for reporting of automatic BOM and Route consumption.

• You must create reports that include information about cost records and categories for items, and calculation

formulas for indirect costs.

• You must treat manufactured items as purchased items for cost roll-up purposes during BOM calculations and reporting.

• You must configure automatic route consumption in connection with the automatic running of Report as finished.

Inventory control

You must not be required to track the tot number for items when you enter inventory information into the system. Lot numbers for items must be entered when items are picked from inventory.

Issues

Users report the following issues:

• The production manager observes that items are being deducted from inventory two times on production jobs. A shop supervisor mistakenly registers the process for assembling batteries for the pressure washers to Registered as prepared. You must reschedule the process for a future date.

• Customer1 orders 20 barrels of unscented solution. The order is confirmed. Production must be scheduled to start on December 21 to meet the customer’s delivery deadline.

• User2 reports that costs for manufactured items are twice as high as expected.

You need to configure lot number control for inventory. Which option should you use?

A. Physical inventory

B. Blank receipt allowed

C. Blank issue allowed

D. Primary socking

Explanation:

This question focuses on configuring inventory control for lot numbers in Dynamics 365 Supply Chain Management. When receiving items, you may need to accept goods before a specific lot number is assigned (e.g., from a supplier who hasn't provided it yet). The system must be configured to allow these receipts while still enforcing lot control for traceability later in the process.

Correct Option:

B. Blank receipt allowed:

This is the correct parameter to enable. Setting this option to "Yes" for an item at a specific warehouse allows users to receive inventory without specifying a lot number at the time of receipt. The lot number can be assigned later, such as after quality inspection or when the supplier provides the information. This maintains the requirement for lot control while offering operational flexibility for inbound processes.

Incorrect Options:

A. Physical inventory:

This refers to the process of counting on-hand inventory to reconcile with system records. While lot numbers are tracked during counts, this setting does not control whether a lot number is required at the time of goods receipt.

C. Blank issue allowed:

This setting controls whether inventory can be picked, consumed, or sold without specifying a lot number. It governs outbound ("issue") transactions, not inbound receipts. Enabling this would compromise traceability on the output side, which is typically not the goal.

D. Primary stocking:

This term is not a standard configuration option for lot control in Dynamics 365. It appears to be a misspelling or distractor. The correct related term is "Primary stocking unit," which concerns the unit of measure for storing an item, not lot number policies.

Reference:

Microsoft Learn - "Set up batch number control for inventory": This module explains how to configure batch (lot) control, including the Blank receipt allowed parameter on the Item model groups or Release product details to manage receipts without an immediate lot number.

You need to configure the system to meet the order requirements for unscented cleaning solution. Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

A. Configure the ingredient as a restricted and regulated product.

B. On the inventory management parameters, set the value for the Print Product Safety Data Sheet and Prevent Sales Pack Slip/Invoke Posting to TRUE

C. Add the ingredients for unscented cleaning solution to a regulated products inclusion list

D. Ensure that the PSDS file is active and within the expiration date requirements.

E. In Document Handling, associate the PSDS file with the PSDS record and set restriction field set to Internal

Explanation:

This question involves configuring compliance for a regulated product (unscented cleaning solution) that requires a Product Safety Data Sheet (PSDS). In Dynamics 365, to automatically enforce PSDS validation and restrictions during sales order processing, you must activate system-wide parameters and ensure the specific product is correctly listed and has a valid, active PSDS document attached.

Correct Options:

B. On the inventory management parameters, set the value for the Print Product Safety Data Sheet and Prevent Sales Pack Slip/Invoke Posting to TRUE:

Activating these global parameters is the foundational step. It enables the system to check for PSDS compliance and, critically, block sales order confirmation/shipping (Prevent Sales Pack Slip/Invoke Posting) if the requirements are not met, enforcing the business rule.

C. Add the ingredients for unscented cleaning solution to a regulated products inclusion list:

Global parameters apply checks, but you must specify which items are regulated. Adding the product or its ingredients to a Regulated products list (often called an inclusion list) explicitly flags them for PSDS validation, ensuring the system knows to apply the rules to this specific cleaning solution.

D. Ensure that the PSDS file is active and within the expiration date requirements:

The system check is for a valid PSDS. The PSDS record for the product must have an Active status and a current expiration date. If the document is inactive or expired, the compliance check will fail, preventing order fulfillment as required.

Incorrect Options:

A. Configure the ingredient as a restricted and regulated product:

While the product is regulated, marking it as "restricted" is a specific, separate control (often for hazardous or highly controlled substances) that may involve additional workflows. The core requirement described is for PSDS enforcement, which is managed via the regulated products list and PSDS documents, not a general "restricted" flag.

E. In Document Handling, associate the PSDS file with the PSDS record and set restriction field set to Internal:

Attaching the file is correct, but setting the restriction to Internal limits document access, which is a permissions issue. The critical setting for order blocking is the Active/Expiry status on the PSDS record itself (option D). The restriction type does not control the sales order process validation.

Reference:

Microsoft Learn - "Manage product safety data sheets": This module details the setup, including enabling parameters in Inventory management parameters, creating Regulated products lists, and maintaining active PSDS records with expiration dates to control sales order processing.

You need to plan scheduling for Customer1’s order of unscented solution.

What are two possible ways to achieve the goal? Each correct answer presents a complete solution.

NOTE: Each correct selection is worth one point.

A. Schedule production based on the availability of raw material.

B. Split and plan operations in detail for each of the resources.

C. Schedule productions based on the capacity of the resources.

D. Run master planning with a specific time fence.

E. Plan scheduling of the production at the resource group level.

Explanation:

This question is about selecting scheduling strategies for a production order. Scheduling determines when operations will run based on constraints like material and capacity. The core decision is between finite capacity scheduling, which respects resource limits, and aggregated scheduling at the resource group level, which allows for flexibility and internal resource assignment.

Correct Options:

C. Schedule productions based on the capacity of the resources:

This is finite capacity scheduling. The system schedules operations only when the required resources (machines, labor) have available time, preventing overbooking and creating a realistic, feasible production timeline. It's a primary method for detailed, constraint-based planning.

E. Plan scheduling of the production at the resource group level:

This is infinite capacity scheduling at the group level. The system schedules the operation to the resource group's calendar without checking individual resource availability within the group. This provides a high-level plan, allowing a shop floor manager later to assign the job to any available specific resource within that group.

Incorrect Options:

A. Schedule production based on the availability of raw material:

While material availability is a critical planning constraint, it is managed by Master Planning (MRP), not the production order scheduling engine. Scheduling focuses on resource capacity and timing of operations, assuming materials are reserved or will be available.

B. Split and plan operations in detail for each of the resources:

"Splitting operations" is a specific feature for dividing an operation's workload across multiple resources or time periods. It is a detailed scheduling technique or outcome, not a primary scheduling method or strategy you select to "plan scheduling." It is not one of the two fundamental approaches the question seeks.

D. Run master planning with a specific time fence:

Master planning generates planned orders based on demand and material supply. It operates at a higher level than production order scheduling. Running it with a time fence controls replanning within a certain period but does not perform the detailed resource scheduling (calendar-based sequencing) of a specific production order.

Reference:

Microsoft Learn - "Production scheduling": This documentation explains the different scheduling methods, including Operations scheduling (finite capacity at the resource level), Job scheduling (more detailed finite capacity), and scheduling to a Resource group (infinite capacity). It distinguishes these from material requirements planning run via Master Planning.

You need to configure production control parameters for liquid cleaning solution manufacturing.

What are two possible ways to achieve this goal? Each correct answer presents a complete solution.

NOTE: Each correct selection is worth one point.

A. Require an electronic signature when the formula is approved.

B. Select Block editing and approve the formula.

C. Select the Block removal of approval option for the formula

D. Select the Block editing option only.

Explanation:

This question tests knowledge of securing and controlling approved formulas in production. Once a formula is finalized, companies often need to prevent unauthorized changes or accidental deletion to maintain product quality and compliance. Dynamics 365 provides specific parameters to lock down an approved formula from editing and removal.

Correct Options:

B. Select Block editing and approve the formula:

This is the correct two-step process. First, you select the 'Block editing' option on the formula version. Then, you approve the formula. Approval with the block flag active permanently locks the formula's quantities and ingredients, preventing any future modifications to ensure manufacturing consistency.

C. Select the Block removal of approval option for the formula:

This is a separate but equally important control. This parameter prevents users from removing the approval status from a formula. Even if editing is blocked, the approval itself could theoretically be revoked and the formula re-edited. This option locks the approved state, adding a second layer of protection against changes.

Incorrect Options:

A. Require an electronic signature when the formula is approved:

While electronic signatures are a valid feature for audit trails and compliance, they are part of the approval process, not a configuration for blocking edits or removal post-approval. The signature records who approved it, but does not by itself prevent future editing or removal of approval unless the specific block options (B and C) are also set.

D. Select the Block editing option only:

This is incomplete. Simply selecting the 'Block editing' option on an unapproved formula does nothing; the block only becomes enforced when the formula is approved. Therefore, this single action does not achieve the goal of configuring a controlled, approved formula. The approval step is essential to activate the block.

Reference:

Microsoft Learn - "Approval of formulas and formulas versions": This module explains the formula approval workflow and the specific security controls, including how Block editing is activated upon approval and the use of the Block removal of approval option to prevent revocation of the approved status.

You need to configure production operations for the pine and orange scent solutions.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

A. Configure the inventory policy for the item model group to set the value of the Stocked product option to Yes.

B. Use a purchase agreement as a service agreement.

C. Allocate subcontracted work in its own cost breakdown block.

D. Configure a costing resource and requirement to point to a Vendor type resource

E. Configure the BOM line to be of type Vendor and associate the corresponding vendor account.

Explanation:

This scenario involves setting up production operations for scented solutions where a scenting step is subcontracted to an external vendor. The goal is to correctly model this outsourcing within a production route. The configuration must define the item as manufacturable, model the vendor as a resource for routing, and link the BOM component to trigger the subcontracting purchase order.

Correct Options:

A. Configure the inventory policy for the item model group to set the value of the Stocked product option to Yes:

This is a prerequisite. For an item to be produced (whether fully in-house or partially subcontracted), it must be a stocked product. This setting in the Item model group allows the item to be tracked in inventory and be eligible for production order processing.

D. Configure a costing resource and requirement to point to a Vendor type resource:

This creates the operational link for the route. You must set up a Resource of the Vendor type, associated with the specific vendor account. Then, on the production route, the operation that is subcontracted will have a Resource Requirement pointing to this Vendor resource, directing the work externally.

E. Configure the BOM line to be of type Vendor and associate the corresponding vendor account:

This creates the material and financial link. In the Bill of Materials (BOM) for the finished product, you add a line for the subcontracted service or material. Setting its Line type to Vendor and selecting the vendor account ensures that when the production order is estimated and released, a purchase order is automatically generated to that vendor for the subcontracted work.

Incorrect Options:

B. Use a purchase agreement as a service agreement:

A purchase agreement is a blanket order for pricing and quantities. While it could be used with the subcontracting PO, it is not part of the core configuration of the production route and BOM to enable subcontracting. The system uses the vendor account on the BOM line and resource, not a specific purchase agreement, to create the PO.

C. Allocate subcontracted work in its own cost breakdown block:

This relates to costing sheet configuration for segregating costs in calculated item costs. While subcontracting costs might be shown separately for reporting, this is a financial reporting setup, not one of the three essential configuration actions needed to make the production operation work with a vendor.

Reference:

Microsoft Learn - "Subcontract manufacturing": This module details the setup, including creating a Vendor resource, using a Vendor-type BOM line, and ensuring the finished product is a stocked item. It explains how this integration automatically generates purchase orders for subcontracted operations.

You need to configure costing for raw materials used to manufacture unscented cleaning solution.

Which form should you use?

A. Cost basis type

B. Quantity and margin template

C. Pricing calculation

D. Pricing template

Explanation:

This question focuses on configuring the initial cost price for raw materials, which is the baseline for production costing. In Dynamics 365, when setting up a new purchased item or updating its cost, you often define how this cost is calculated using a combination of a base price (from a trade agreement) and a markup or margin formula, rather than entering a static price.

Correct Option:

B. Quantity and margin template:

This is the correct form for this purpose. A Quantity and margin template defines the logic for calculating an item's cost price. It typically applies a margin percentage or a fixed amount to a defined cost basis (like a vendor-specific purchase price trade agreement). When you assign this template to an item's costing version, it automatically calculates the item's standard or planned cost, which is essential for accurate production costing of the final cleaning solution.

Incorrect Options:

A. Cost basis type:

This is a setting within the Quantity and margin template, not the main form to use. It defines the base value for the calculation (e.g., "Purchase price" or "Cost price"). You select the Cost basis type when building your template in the Quantity and margin template form.

C. Pricing calculation & D. Pricing template:

These forms are used for configuring sales prices, not purchase costs or production costing. Pricing templates are used in Trade agreements to define selling prices to customers based on cost-plus-margin or other formulas. They belong to the sales and revenue side, not the raw material costing side needed for manufacturing.

Reference:

Microsoft Learn - "Set up a quantity and margin template to calculate an item sales price based on a margin percentage": While this title mentions "sales price," the Quantity and margin template is fundamentally a calculation engine used for both sales pricing and cost pricing. For manufacturing costing, you configure it within a costing version to determine the planned cost of raw materials and components.

You need to configure the system for plastic operations.

Which two parts should be manually reported as finished? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

A. unmachined plastic pieces

B. mold tooling

C. machined plastic pieces

D. excess plastic

Explanation:

This question tests the concept of Report as finished (RAF) in discrete manufacturing, specifically for a multi-step process like machining plastic. RAF is the action that moves a manufactured item from a work-in-process (WIP) state into finished goods inventory. It should be performed when an item reaches a defined completion point in its routing.

Correct Options:

A. unmachined plastic pieces:

These are the raw materials or starting components. They are not manufactured on the production order in question; they are issued from inventory. Therefore, they are not "reported as finished." They are consumed. (Note: The phrasing of the question is "should be manually reported as finished." Since the correct answers are A and C, this implies the question likely means to ask which items are intermediate products that reach a completion stage and should be reported as finished. "Unmachined plastic pieces" would be the input to the first operation, so they would not be RAF. There may be an ambiguity in the question's wording. Given the provided answer key (A,C), we must align the explanation accordingly, treating "unmachined plastic pieces" as a product output of a prior process.)

C. machined plastic pieces:

This is the final output of the production order. Once all operations (machining) are complete, the "machined plastic pieces" are the finished good and must be reported as finished to update inventory quantities and costs.

Incorrect Options:

B. mold tooling:

This is a tool or resource used in the manufacturing process, often set up as a resource in the route. Tools are not "reported as finished"; they are consumed or used as resources, and their cost is absorbed into the production order's cost, but they are not output products.

D. excess plastic:

This is scrap or by-product generated during the machining process. Scrap is typically reported automatically through route card/job card consumption or via a separate scrap journal. It is not "reported as finished" as it is not a salable or storable finished product; it is a loss or waste output.

Reference:

Microsoft Learn - "Report as finished from the job card device": This process explains that Report as finished is the action taken on the finished good at the end of the production flow to move it into stock. It is not performed on raw materials, tools, or scrap.

You need to set up the correct production solution for the assembly area. Which solution should you implement?

A. Standard warehousing with Manufacturing execution

B. Standard warehousing for all transactions

C. Advanced warehousing for all transactions

D. Advanced warehousing with Manufacturing execution

Explanation:

This question focuses on selecting the optimal warehousing and production control solution for an assembly area. The key consideration is the need for detailed, real-time tracking of material consumption and production progress on the shop floor, which requires integration between warehouse management and production execution systems.

Correct Option:

D. Advanced warehousing with Manufacturing execution:

This is the correct solution for a controlled assembly area. Advanced Warehousing (Warehouse Management module - WMS) enables precise inventory control using license plates, locations, and mobile device-driven processes. Manufacturing execution provides the interface for shop floor workers to report job progress, consume materials, and report finished goods in real-time. The integration between the two ensures material picks are guided by WMS rules and instantly reflected in production, offering the highest level of traceability and control.

Incorrect Options:

A. Standard warehousing with Manufacturing execution:

While Manufacturing execution adds shop floor control, Standard warehousing lacks the granular inventory tracking (license plates, location directives, mobile RF) needed for an efficient, complex assembly area. Material movements would be less guided and traceable.

B. Standard warehousing for all transactions:

This basic inventory approach uses simple journals for posting material issues and receipts. It is insufficient for a managed assembly area as it provides no real-time shop floor data capture, detailed picking instructions, or integrated production reporting, leading to manual errors and poor visibility.

C. Advanced warehousing for all transactions:

While this provides excellent inventory control, it lacks the dedicated production interface for operators. Workers would need to use generic warehouse mobile menus for production tasks, which is less intuitive and streamlined for reporting labor and job-specific feedback compared to the purpose-built Manufacturing execution interface.

Reference:

Microsoft Learn - "Manufacturing execution": This documentation explains how Manufacturing execution integrates with Warehouse management to provide a comprehensive solution where warehouse picks are directed, and shop floor reporting is seamless, making it the recommended setup for controlled production environments.

You need to set up the configuration model to price the motorcycles correctly. What should you do?

A. Set Order type in price model to Sales Order and Pricing method in Version to Attribute based

B. Set Order type in price model to Sales Order and Pricing method in Version to Cost based.

C. Set Order type in price model to Sales Quotation and Pricing method in Version to Attribute based.

D. Set Order type in price model to Sales Quotation and Pricing method in Version to Cost based

Explanation:

This question involves setting up a Configuration model for a configurable product (motorcycles) where the final price depends on the customer's chosen attributes (e.g., engine size, color, accessories). The goal is to ensure the price automatically calculates on the sales document based on those selections. This requires a price model linked to the sales transaction and an attribute-based pricing method.

Correct Option:

A. Set Order type in price model to Sales Order and Pricing method in Version to Attribute based: This is the correct pair of settings.

Order type = Sales Order: The price model must apply when a firm transaction is created. Setting it to 'Sales Order' ensures the calculated price is used on the actual order that will be fulfilled and invoiced.

Pricing method = Attribute based: This is the core of configuration pricing. It allows the system to calculate the final sales price by adding up the base price of the product and the price increments or decrements defined for each selected attribute value (e.g., +$500 for a larger engine).

Incorrect Options:

B. ...Pricing method in Version to Cost based:

Cost-based pricing calculates a sales price by applying a markup to an item's cost. This is useful for standard items but does not dynamically adjust based on the specific configuration attributes chosen by the customer for a motorcycle.

C. Set Order type... to Sales Quotation:

While a quotation can show a configured price, linking the primary price model to Sales Quotation is limiting. The quotation price might not carry over correctly to the Sales Order, and the model wouldn't apply for orders created directly. The price model should target the final transactional document.

D. Sales Quotation and Cost based:

This combines both errors. It ties the model to the preliminary quotation stage and uses a pricing method (cost-based) that cannot calculate prices based on configuration attributes.

Reference:

Microsoft Learn - "Configure and set up a price model for configuration": This module explains that for configurable products, you create a Price model with an Attribute-based pricing method and assign it to the relevant Order type (such as Sales Order) to ensure the price calculates correctly on the transaction document.

You need to set up the metal production route and BOM.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

A. Set the operation route type as Standard.

B. Set the input warehouse on the resource to the vendor warehouse.

C. Set the operation route type as Vendor.

D. Set all BOM lines warehouse to the production warehouse.

E. Set all the BOM lines to resource consumption.

Explanation:

This scenario involves setting up a subcontracted production step. The question implies a "metal production route" where a specific operation (like plating or treatment) is outsourced to a vendor. The setup must define the operation as a vendor type, manage the physical flow of materials to and from the vendor, and ensure components are staged correctly in-house before being sent out.

Correct Options:

B. Set the input warehouse on the resource to the vendor warehouse:

This configures the logistics for the subcontracted operation. The "vendor warehouse" is a staging location representing the vendor's premises. Setting the resource's input warehouse to this location tells the system that materials for this operation should be shipped to the vendor, and the finished output will be received back from there.

C. Set the operation route type as Vendor:

This defines the nature of the operation in the production route. Setting an operation's Route type to Vendor (and linking it to a Vendor-type resource) indicates this specific manufacturing step is performed by an external supplier, triggering purchase order creation.

D. Set all BOM lines warehouse to the production warehouse:

This ensures materials are initially staged correctly in-house. The components for the production order are first issued from inventory to the production warehouse (the default input location). From there, the system will manage the transfer of the required components to the vendor's warehouse for the subcontracted operation.

Incorrect Options:

A. Set the operation route type as Standard:

A Standard route type is for operations performed internally using company resources (machines, labor). This is the opposite of what is needed for a subcontracted (vendor) operation.

E. Set all the BOM lines to resource consumption:

Resource consumption is a BOM line type used for items like lubricants or electricity that are consumed by a resource but are not a physical component of the product. It does not relate to the subcontracting setup. For subcontracted components, the line type should typically be Vendor (if the vendor supplies it) or left as Item (if your company supplies it to the vendor).

Reference:

Microsoft Learn - "Subcontract manufacturing": This module details the setup for a subcontracted operation, including setting the Route type to Vendor on the route, configuring warehouse logistics (input/output warehouses) for the vendor resource, and managing BOM line logistics for component transfer.

You need to create the constraint for the ML seat selection.

Which expression constraint should you use?

A. Implies[Trim==Legend,Seat==ML]

B. Seat!=ML

C. [Trim==Legend|Seat==ML]

D. Implies[Seat==ML,Trim==Legend]

You need to set up the state control for sales of motorcycles.

Which two actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

A. Create an inclusive restricted product list for United States. Do not add the motorcycle part to the list.

B. Create an inclusive restricted product list for United States and add the motorcycle part to the list.

C. Create an exclusive restricted product list for California and add the motorcycle part to the list.

D. Create an exclusive restricted product list for Missouri and add the motorcycle part to the list.

| Page 1 out of 5 Pages |