Topic 4: Adventure Works Cycles (Case 2)

You need to recommend a process for planned orders that will not be firmed.

What should you recommend?

A.

Change the status to Unprocessed

B.

Set the planned order to Completed

C.

Delete the planned order

D.

Change the status to Approved

E.

Remove the planned order from selection

Set the planned order to Completed

Reference:

https://docs.microsoft.com/en-us/dynamics365/supply-chain/master-planning/maintainplanned-

orders

You need to identify all potential gaps in the master planning solution for Adventure Works’

implementation.

What should you do?

A.

Read the release notes and master planning entries in the Microsoft Ideas portal.

B.

Finish relevant material requirements planning system configurations and data imports

and run a fit analysis.

C.

Identify the gaps through the known issues in Lifecycle Services.

D.

Upload all task recordings for MRP business processes into Azure DevOps for analysis.

Finish relevant material requirements planning system configurations and data imports

and run a fit analysis.

Reference:

https://docs.microsoft.com/en-us/dynamics365/supply-chain/master-planning/planningoptimization/

planning-optimization-fit-analysis

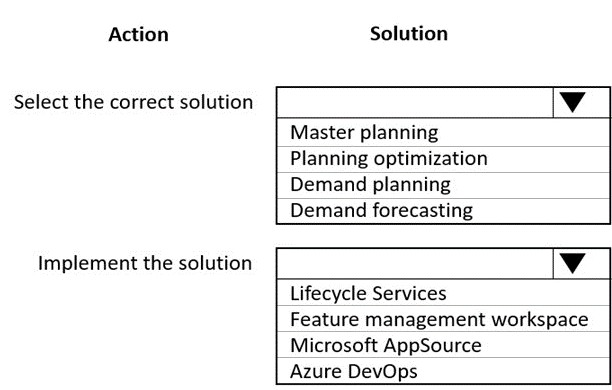

You need to implement the master planning solution for Adventure Works.

Which solutions should you use? To answer, select the appropriate option in the answer

area.

NOTE: Each correct selection is worth one point.

Explanation:

Table

Description automatically generated

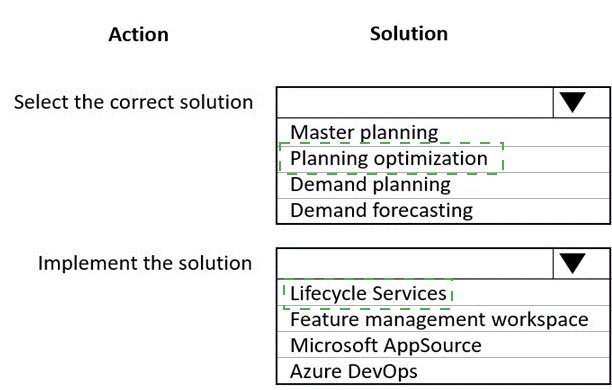

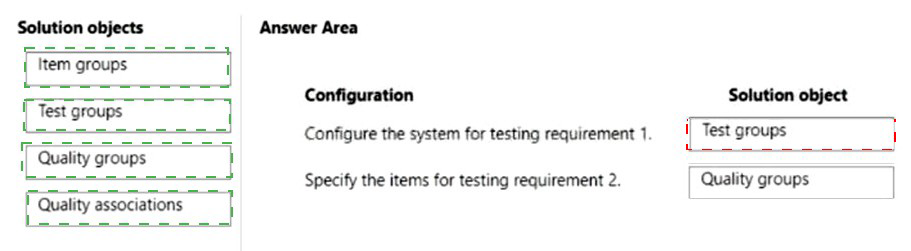

You need to configure quality controls.

Which solution objects should you configure? To answer, drag the appropriate solution

objects to the correct configurations. Each solution object may be used once, more than

once, or not at all. You may need to drag the split bar between panes or scroll to view

content.

NOTE: Each correct selection is worth one point.

Explanation:

Box 1: Test groups

Requirement 1: 100 percent of all nutritional supplements and 50 percent of all energy

drinks must be tested when production orders are completed. After a product is in testing,

100 percent of all tests must be completed.

You use the Test groups page to set up, edit, and view test groups and the individual tests

that are assigned to them. The upper part of the page shows the test groups, and the lower part shows the tests that are assigned to a selected test group.

You assign several policies to a test group, such as a sampling plan, an acceptable quality

level (AQL), and the requirement for destructive testing. Then, when you assign an

individual test to a test group, you define additional information, such as the sequence,

documents, and validity dates. For a quantitative test, the information that you define also

includes the acceptable measurement values. For a qualitative test, the information

includes the test variable and default outcome.

The test group that is assigned to a quality order defines the default set of tests that must

be performed on the specified item. However, you can add, delete, or change tests for the

quality order. Test results are reported for each test on a quality order.

Box 2: Quality groups

Requirement 2: 75 percent of all nutritional supplements and energy drinks should be

tested against their required tests during an outbound process.

Quality groups

A quality group represents common testing requirements for items.

Use and create item quality groups to logically group products so that they can be assigned

to quality associations for the automatic generation of quality orders.

Example of an item quality group

A manufacturing company purchases various raw materials that have the same testing

requirements for incoming inspection. Therefore, the company defines a quality group and

then assigns the item numbers that are associated with the raw materials to that group.

Later, the company purchases a new type of raw material that has the same testing

requirements. Instead of setting up new testing requirements for the new material, the

company adds the item number for the new material to the existing quality group.

You need to configure the system for the customer tier B pricing.

What should you do?

A.

Configure an item sales control for the item

B.

Enable the customer group in the Activate price/discount form

C.

Assign the product filter code for the item to the customer tier B customer group

D.

Assign the item to the customer tier B price group.

E.

Approve and confirm the trade allowance agreement.

Approve and confirm the trade allowance agreement.

Explanation:

Note: Customers are categorized into four pricing tiers (A, B, C, and D) based on sales

volume over the past 12 months.

Promotional fund and Trade allowance agreement

A trade allowance agreement is an incentive program where pay-for-performance monetary

rewards are offered to customers that achieve specific volume targets and/or behavioral

goals. Promotional funds are budgeted expenditures. In that way, the promotional

campaigns can be captured.

Reference: https://docs.microsoft.com/en-us/dynamics365/supply-chain/salesmarketing/

trade-allowance#promotional-fund-and-trade-allowance-agreement

Trey Research is now live on Dynamics 365 Supply Chain Management.

You need to apply the new cost model for the apparel items.

What should you do?

A.

Run Inventory close.

B.

Close all production orders.

C.

Configure Backflush costing.

D.

Run a BOM calculation.

Run Inventory close.

Explanation:

Apparel items will not be upgraded to the new costing method until after the go-live date

due to resourcing and implementation limitations from the apparel team. The inventory close process settles issue transactions to receipt transactions, based on the

inventory valuation method that is selected in the item’s item model group. As part of the

settlement process, you can specify that the general ledger should be updated, so that it

reflects the adjustments that have been made. However, until inventory close or

recalculation has been run, issue transactions are posted at the calculated running average

cost price.

After inventory close, you can no longer post in periods that are before the inventory

closing date that you set, unless you reverse a completed inventory close process. For

example, if inventory close is run for the period that ends on January 31, you can't post

transactions that have a date that is earlier than January 31.

Reference: https://docs.microsoft.com/en-us/dynamics365/supply-chain/costmanagement/

backflush-costing

https://docs.microsoft.com/en-us/dynamics365/supply-chain/cost-management/bomcalculations

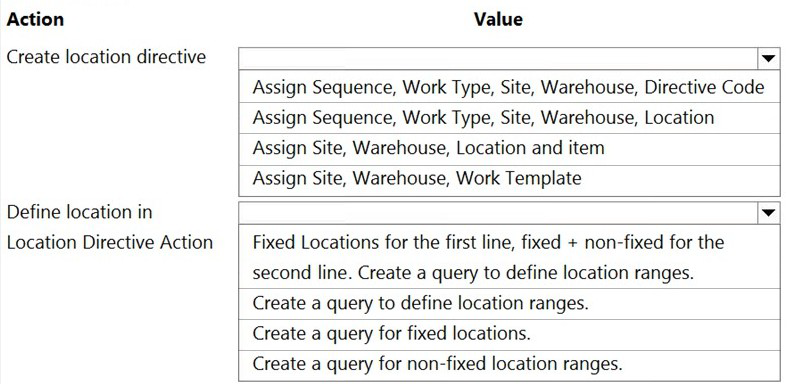

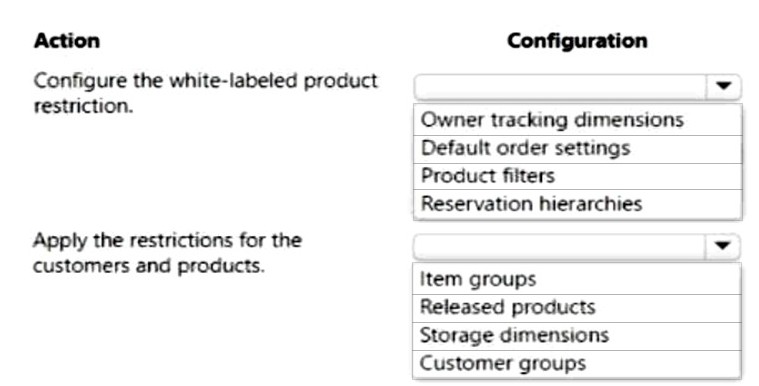

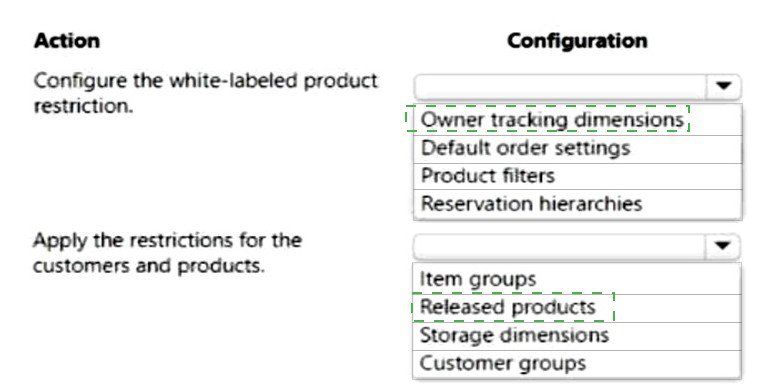

You need to configure the products for the requirements.

Which configuration should you use? To answer, select the appropriate options in the

answer area.

NOTE: Each correct selection is worth one point.

Explanation:

Box 1: Owner tracking dimensions

Requirements. White labeling

• Trey Research wants to start white labeling its products under the brands of major

nutritional retail store brands. These products would only be sold to specific customers.

• Trey Research will provide and maintain a 'Compare to' price for customers to use to

compare the white-labeled products. This Compare to price will also be the default item

price for the customer if the customer accidentally lets a contract price expire.

• The configuration of these restrictions must be applied automatically when creating new

products for those customers.

The tracking dimension is a lower-level assortment of products, irrespective of whether it is a serial number for electronic inventory items or a batch number.

Box 2: Released product

To change the Tracking Dimension Group for Products in Dynamics Operations, you need

to change settings on both on the product level and the released product level. However,

you need to delete the tracking dimension group at the product level prior to making

changes to the corresponding released product.

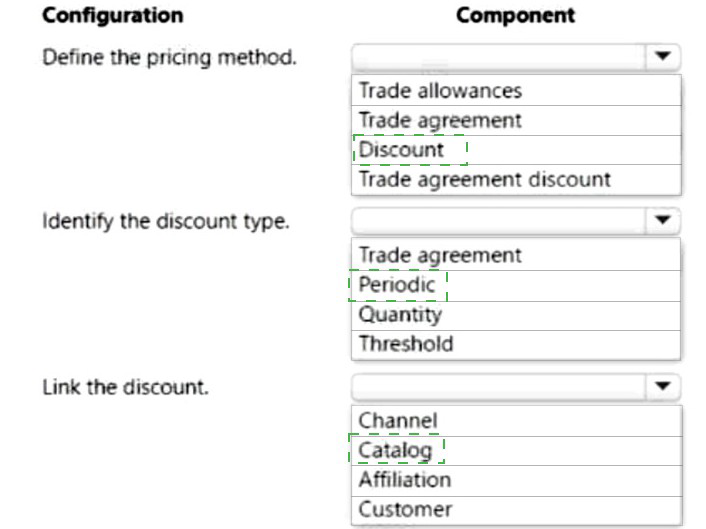

You need to configure the extreme sports discounts.

Which component should you use? To answer, select the appropriate options in the answer

area.

NOTE: Each correct selection is worth one point.

You need to define the number of quarantine zones.

How many should you define?

A.

1

B.

2

C.

4

D.

6

E.

8

4

Scenario:

* Damaged products must be placed in one of four bins (based on product type) during the

inspection process.

* You must define quarantine zones to optimize product visibility throughout the testing

process.

Four bins for the damaged product types, so we need four quarantine zones.

Note: You use the Quarantine zones page to define zones that can be assigned to

nonconformances.

Examples of quarantine zones

Example 1

You work at an electronics manufacturing company that produces and distributes

televisions, speakers, and media players. In this case, you can configure a quarantine zone

to represent each type of product.

Example 2

Three bins and two racks are used to store items that are nonconforming. In this case, you

can configure five quarantine zones, one for each bin and each rack.

Reference: https://docs.microsoft.com/en-us/dynamics365/supply-chain/inventory/qualityquarantine-

zones

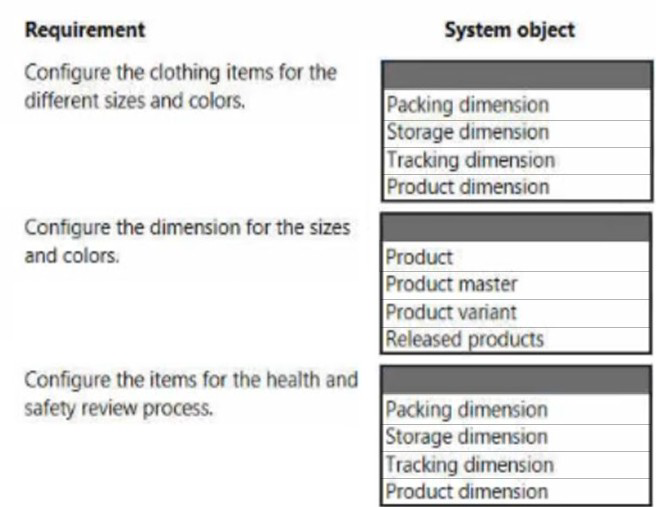

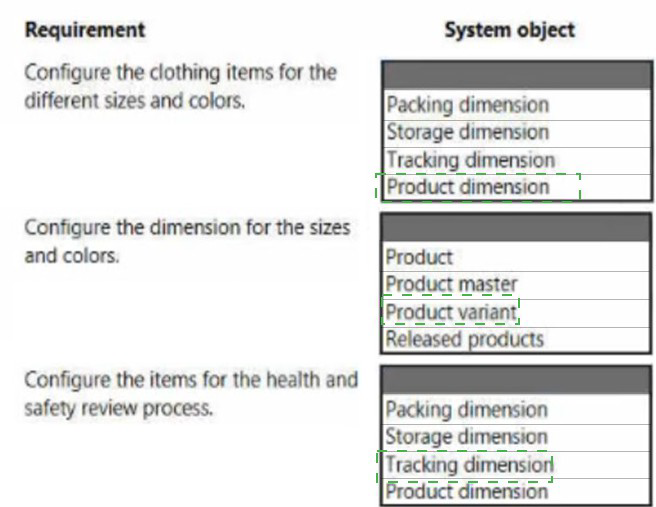

You need to configure the products in Dynamics 365 Supply Chain Management for the

requirements.

Which system objects should you use? To answer, select the appropriate options in the

answer area.

NOTE: Each correct selection is worth one point.

Box 1: Product dimension

There are five product dimensions: color, configuration, size, style, and version.

Box 2: Product variant

Product variants are also referred to as items. An item is a tangible product, which isn't the

same as a service.

A product variant can be generated based on the product dimension values.

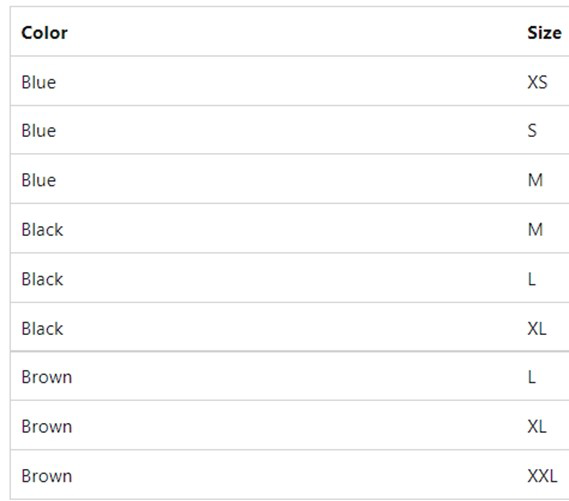

Example

A company sells denim jeans. The item, Jeans, uses the color and size product

dimensions. The jeans are sold in three different colors and six different sizes. The colors

are blue, black, and brown. The sizes are XS, S, M, L, XL, and XXL. Not all sizes are

available in all three colors. If all combinations were available, there would be 18 different

types of jeans. However, in this example, only the following nine product variant

combinations are produced.

Table

Description automatically generated

You need to configure the system to automatically enforce inbound and outbound product

requirements to and from the warehouse.

Which feature should you use?

A.

quality associations

B.

quality orders

C.

quarantine zones

D.

quality tests

E.

nonconformances

quality orders

Note: If products in the warehouse must be blocked from transactions for a specific reason,

such as a health and safety review, warehouse users should be able to block the products

quickly from the ERP system.

You can block inventory items in the following ways:

Manually

By creating a quality order

By using a process that generates a quality order

By using inventory status blocking

Reference: https://docs.microsoft.com/en-us/dynamics365/supplychain/

inventory/inventory-blocking

Question No : 58 - (Topic 5)

Microsoft MB-330 : Practice Test

72

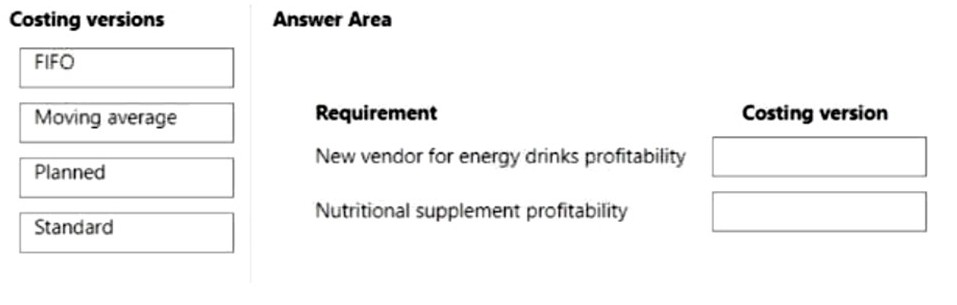

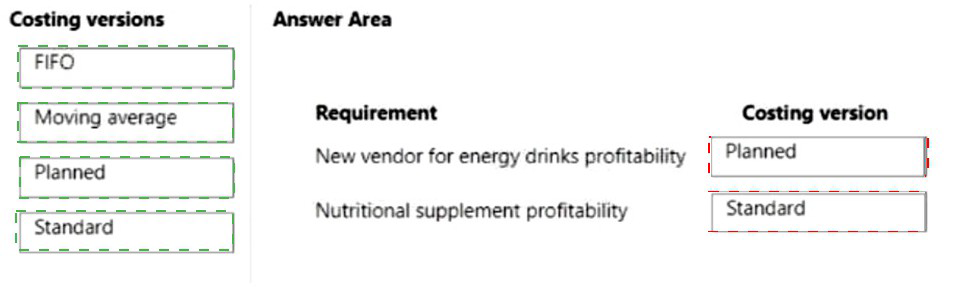

You need to determine the costing versions for the requirements.

Which costing versions should you use? To answer, drag the appropriate costing versions

to the correct requirements. Each costing version may be used once, more than once, or

not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

Explanation:

Box 1: Planned

If a vendor can no longer deliver the raw materials for the energy drinks due to supply

chain issues, the costs for using an alternative vendor to source the raw materials should

be used to determine the impact on profits.

Planned costs

A costing version can contain a set of planned cost records about items and manufacturing

processes. A costing version that contains planned costs is often used to support cost

calculation simulations, such as simulations of the effect that cost changes to purchased

materials or manufacturing processes has on the calculated costs of manufactured items.

The item cost records for planned costs can also be used to support an actual cost

inventory model by providing the initial values for item costs. These values include the

calculation of planned costs for manufactured items.

Box 2: Standard

The profitability for nutritional supplements manufacturing processes needs to be

expressed in terms of the cost categories for routing operations and the calculation

formulas for manufacturing overheads.

Standard costs

A costing version can support a standard cost inventory model for items, where the costing

version contains a set of standard cost records about items and manufacturing processes.

Cost data about manufacturing processes is expressed in terms of the cost categories for

routing operations and the calculation formulas for manufacturing overheads.

| Page 12 out of 34 Pages |

| Previous |